1. The Smallest Contaminants Can Be Crippling

The high-pressure common rail (HPCR) fuel systems used in low-emission diesel engines can be susceptible to damage from contaminants in the same size ranges as bacteria. Engine OEM’s have stringent fuel cleanliness requirements which have resulted in the demand for precision on-board fuel filtration. While diesel fuel cannot be too clean, it can certainly be too dirty. Saving a few dollars using a less efficient on-engine fuel filter may prove costly over the life of the engine.

2. Water Is an Ever-Formidable Enemy

Water can directly contribute to a range of challenges, including rapid fuel filter plugging, fuel instability, corrosion, bacterial growth (fuel bug) and even catastrophic failure of fuel injection systems. While Australian Fuel suppliers take great care to provide the market with clean dry fuel, we must maintain the fuels integrity while its in our custody. Protect storage facilities with quality breathers and routinely test for and remove free water. Many on-engine primary filters are transitioning to advanced coalescing filtration technology featuring multi-layered filter media to collect even finer water droplets.

3. Fuel Additives Require Care

Sulphur presents a range of environmental challenges and many countries have mandated the use of ultra-low-sulphur diesel (ULSD). These modern fuels do not have the natural lubricating properties of older high-sulphur fuels and as such are treated with surfactant-based additives at refinery level to maintain lubrication. Many fuel suppliers also offer premium fuels that include additional additive packages to clean fuel systems and enhance performance. Always consult your OEM and fuel provider before introducing further additive packages to your fuel.

4. Watch Your Biodiesel Blends

Biodiesel and bio-blends provide environmental advantages but may take a little more care to provide trouble free operation. Biodiesel is a solvent and will clean varnishes or lacquers that have built up in infrastructures after years of mineral diesel use. Expect to initially change bulk storage and on-engine filters more frequently when transitioning to biodiesel. Embrace proactive tank maintenance routinely testing for and removing free water and don’t hesitate to seek specialist advice before transitioning.

5. Today's Fuel Filters Have Evolved

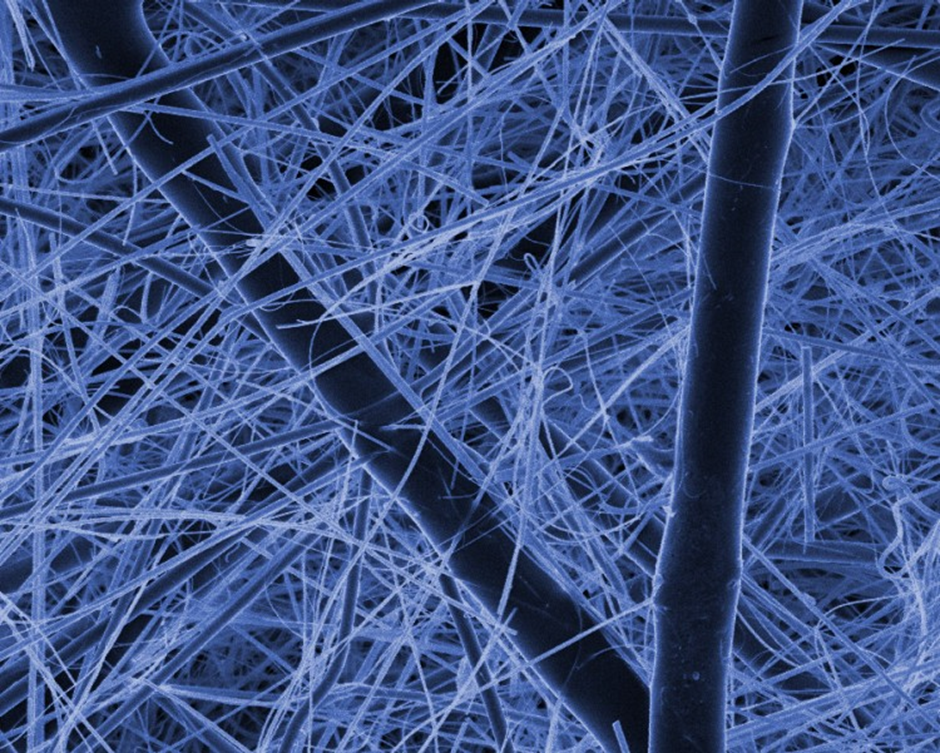

Modern filtration media technologies such as Donaldson’s Synteq XP™ Media feature thermally bonded fibres for a high level of efficiency and contaminant retention.

High-efficiency filters capture and retain greater amounts of fine contaminants than their predecessors. Contamination that may have passed through older generation filters may contribute to rapid plugging of a tighter filter. Proven media technologies like Donaldson’s Synteq XP™ used in the Blue® range of fuel filters provide an industry leading balance of high efficiency, retention, and capacity.

Quality fuel filtration is your frontline defense against downtime and increased operational expenses. Contaminated diesel fuel can have a range of impacts beyond warranty implications and the total cost of ownership.